|

|

|

Preflight PDF files to help you save time and costs, increase customer satisfaction by improving quality control, and allow you to hit deadlines and avoid reprints.

Every day hundreds of thousands of printers, publishers and designers are saving millions and ensuring their quality control by preflighting PDF documents.

Very simply put, preflight is checking the quality of PDF files before they get processed.

Preflight checks whether the characteristics of those files are in sync with your desired output.

Preflight ensures not just the technical content of a PDF file but also the printability of the layout and design based on the printing technique, printing device and substrate used.

|

But why do you need to preflight a PDF file?

They look mighty good on screen and you can print it on your 200€ printer, why can't it be printed on a 300,000€ press? And who pays for reprints?

Many errors that are detected by preflight software, can't be detected in any other way. And those errors do create trouble afterwards! |

|

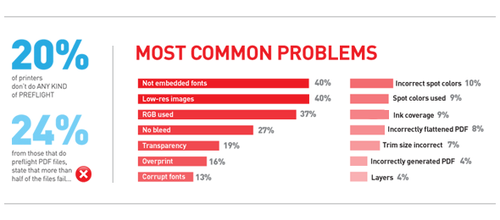

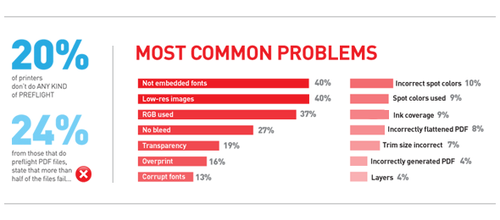

10 most common problems in print

that you can prevent by preflighting your PDF files: |

| |

|

|

|

For print output, the image resolution

needs to be higher than for viewing a PDF on a

screen, a general rule of thumb is the

resolution should be 2 x your halftone screen

ruling. Otherwise you will see jagged edges and

artifacts in the image. |

PitStop

PDF Preflight checks the resolution of

images in your file.

|

|

| |

|

|

|

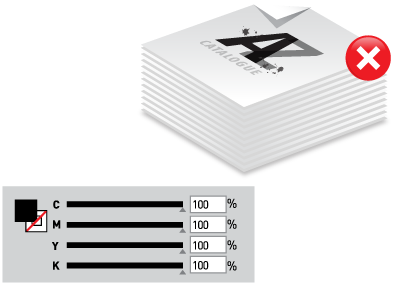

Unintended RGB images in PDF files can

cause unexpected results after processing.

The images could be of low quality, the final

printed color could be incorrect and there may

even be a color shift. |

PitStop

PDF Preflight checks PDF files for RGB

images and even converts them to CMYK.

|

|

| |

|

|

|

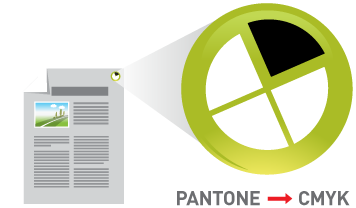

Most designers like to work with spot colors

(e.g. Pantone), especially in logos. But in many

cases, these logos need to be printed

using only CMYK inks, an extra

'dedicated' ink for the spot color is more

expensive. |

PitStop

PDF Preflight checks on presence,

number and suffix of spot colors.

PitStop

PDF Preflight can handle color

conversion from and to spot colors.

|

|

| |

|

|

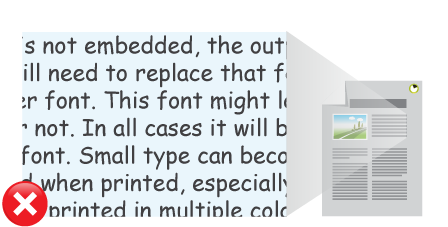

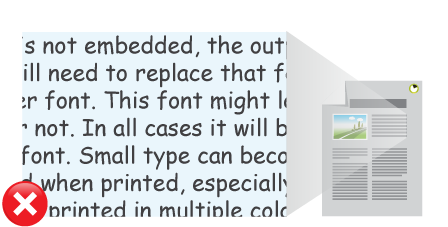

Numerous problems can occur with fonts

E.g. if a font is not embedded, the

output equipment will need to replace that font

with another font. This font might look

similar, or not. In all cases it will be a

different font. Small type can become hard to

read when printed, especially if it's printed in

multiple colors. |

PitStop

PDF Preflight checks font embedding,

font size, font type and number of separations

in combination with font size.

PitStop

PDF Preflight can automatically embed

missing fonts and prevent common font issues.

|

|

| |

|

|

Ever seen a job where a white element looks

great on the screen or paper proof suddenly

disappears when on press? White elements could

be set to "overprint",

which means that the

white ink will be output on top of the inks

below and basically disappear. Unless you are in

packaging or use specific a white ink in your

production process, the white elements should be

set to "knock out". |

PitStop

PDF Preflight can check if white

elements are set to knock out.

PitStop

PDF Preflight can automatically fix

white elements so they knock out.

|

|

| |

|

|

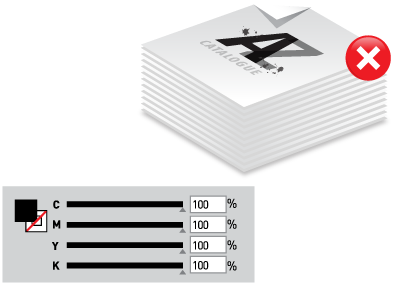

How do you define a nice deep ('rich')

black, one that won't cause trouble on a

printing press? Every company has their

own recipe for a nice black.

But a black that carries too much ink can be a

problem for some printing methods.

A black that's too heavy can cause web breaks on

a web press and marking or set off.

|

PitStop

PDF Preflight can specifically check

for too high Rich Black color values.

PitStop

PDF Preflight can reduce or standardize

the Rich Black values to your own values.

|

|

| |

|

|

|

Although transparency is now a widely accepted

functionality within most design and page layout

applications many printing companies are still

wary of PDF files containing transparency and

like to give them specific attention to ensure

they are processed and imaged correctly.

|

PitStop

PDF Preflight can check files for

transparency.

|

|

| |

|

|

Layers were introduced with PDF version 1.5.

These layers can be visible, or hidden. If your

proofer or your RIP doesn't support PDF v1.5 or

higher and there are layers in the PDF, they

will be placed on top of each other.

If a file contains a hidden layer, which is set

to to 'Always print', it will be printed.

|

PitStop

PDF Preflight can check if hidden

layers are present in the file.

|

|

| |

|

|

|

If a file that contains images or content that

extend to the edge of the page and it contains no or not enough bleed,

white borders can appear after cutting the sheets. |

|

PitStop PDF Preflight can check if

bleed is present in a PDF file.

|

|

| |

|

|

|

Excess ink coverage causes marking from one

sheet to another, long drying times and

increases the risk of spoilage. Wet paper can

cause registration issues and can cause you to

have to slow the performance of a press to

ensure the final printed quality. |

PitStop

PDF Preflight can check and reduce ink

coverage.

|

|

|

|

Enfocus has the right solutions to

guarantee that

PDF's flow reliably through production.

Our solutions come with award winning

Certified

PDF technology and offer correction of the

most

common prepress errors. |

|

|